E-paper and V-Platform in production line optimization

Visionect, 30 Jun 2014

Communication is an important part of both cost optimization and quality assurance when building any product on a factory production line. The communication regularly involves exchange of paper and we set out to improve this using our e-paper solutions and upgrade it for the 21st century.

Production lines have a common need – communication among involved, control of the process and quality assurance.

Communication is an important part of both cost optimization and quality assurance when building any product on a factory production line. The communication regularly involves exchange of documents, mostly in the form of paper that gets checked, stamped, filed with different stickers, bar codes and signatures of people in charge. We set out to improve this communication and upgrade it for the 21st century.

Common need in a variety of production lines

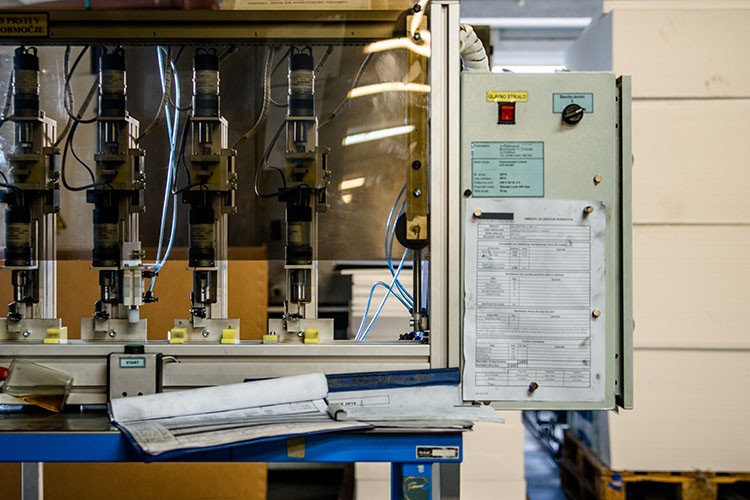

Numerous products are manufactured daily in a variety of production lines. Still all of production lines have a common need – communication among involved, control of the process and quality assurance. Most of these processes involve the use of standardized forms printed on paper.

There is a lot of paper at every workstation and machine.

This paper approach might work well and it can be very well integrated in the overall process. An interesting example of such an approach is how Pipistrel, a hi-tech and environmentally aware manufacturer of advanced light aircrafts handles quality control. To summarize: their intense quality control of each part of the aircraft is followed by approval stickers and bar codes. For the production line all jobs, tasks and actions that need to be performed, as well as all the parts and sub-systems that need to be assembled onto the aircraft, are written onto the inspection sheet. According to the progress, workers and quality control managers sign the sheet daily.

While we think that the (largely paper based) process as it is works really well (even for high-tech companies like Pipistrel), we got inspired by reading how they handle quality control in their complex assembly process. We will show that replacing paper with a digital alternative creates many new opportunities for optimization of the entire production process.

V-Tablet devices used to control production process by a manager.

Advantages of e-paper and our platform

What would a company gain by introducing e-paper into their assembly line process? E-paper is a display with paper-like properties (manufactured by E Ink and others). Coupled with our e-paper platform (V-Platform and our V-Tablet devices) it enables easy, real time automated integration with the company’s information technology system.

Key properties of our system and devices:

- superb visibility in very bright environments, no light pollution and eye friendly,

- dust and water resistance (ip67),

- very low energy consumption and related maintenance,

- extremely low software development costs due to the use of Web technologies,

- centralized control and management tailored for enterprise environments.

We set out to find a local manufacturer with a production line and prove that our platform is perfect for use on production lines by building an e-paper solution they’ll use daily, replacing their current paper setup.

The setup in practice

The company we worked with has a three step production line: entry of all necessary parts, several steps in an assembly process and final test of the product before it gets delivered to a customer. All steps also need to pass quality assurance test in order to proceed to the next stage.

We set out to find a local manufacturer with a production line and prove that our platform is perfect for use on production lines by building an e-paper solution they’ll use daily, replacing their current paper setup.

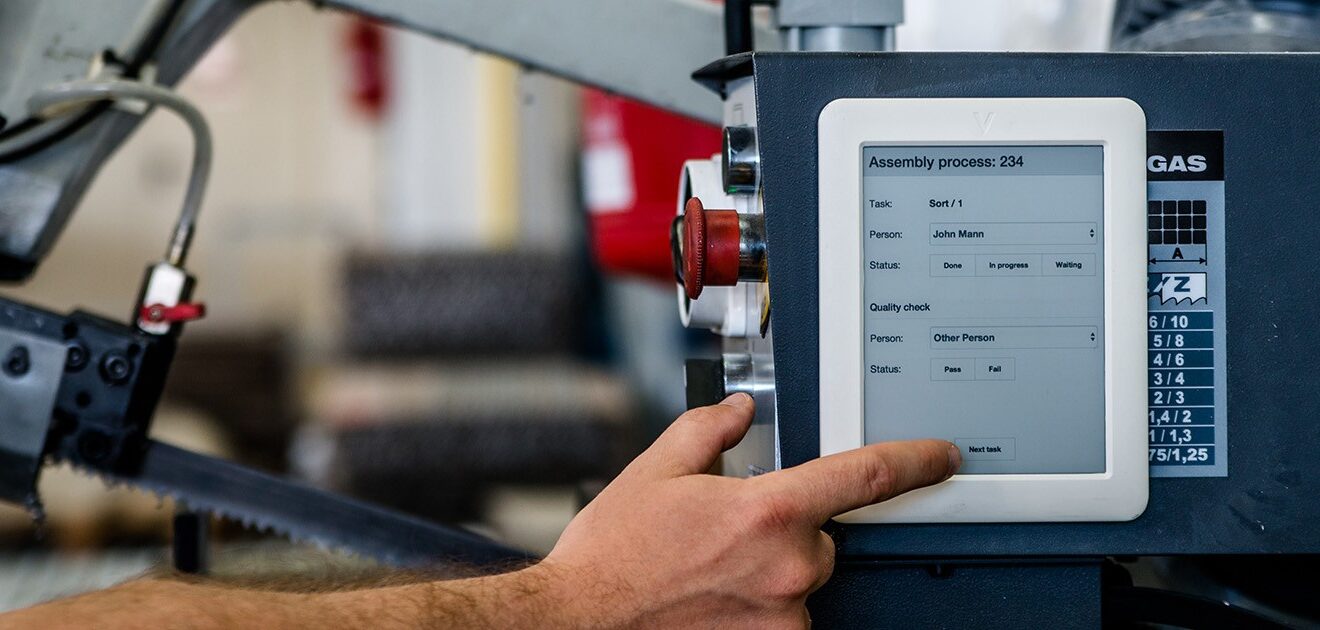

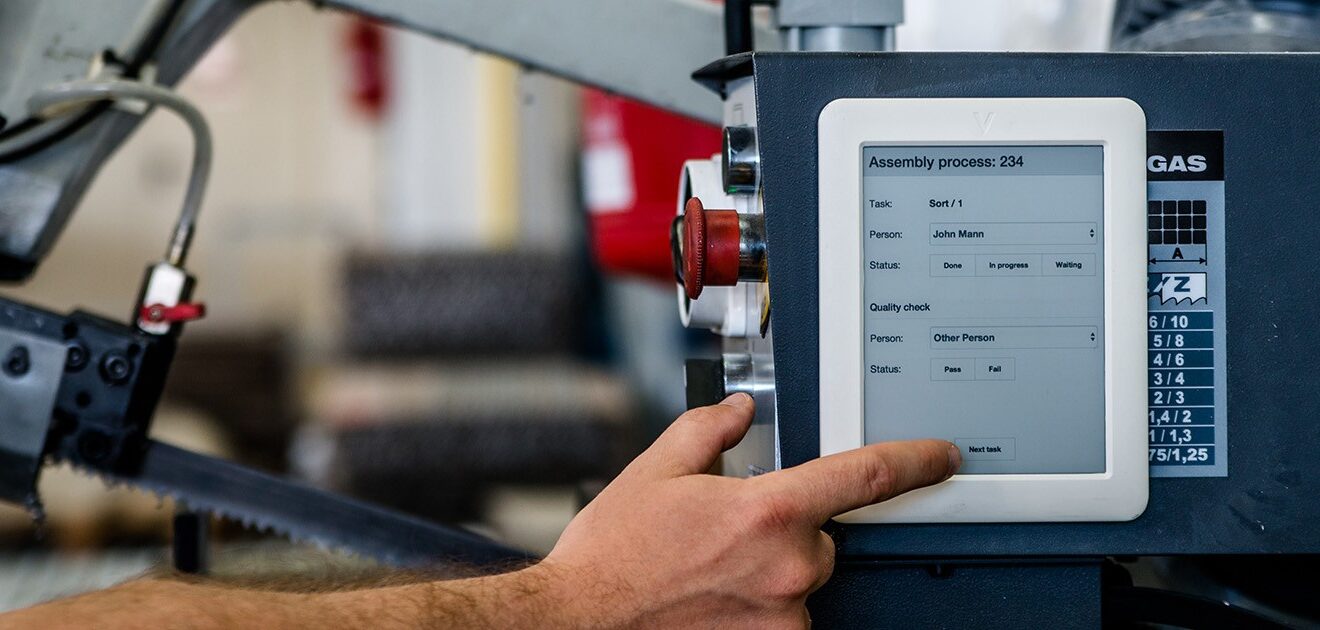

Instead of a form with checklist and quality assurance points printed on paper we use e-paper devices. Our V-Tablet devices are present trough all stages of the production process, mounted on convenient places on each workstation. Old paper layouts are reformatted and shown on the devices with an improved user experience that eases and shortens interaction with documentation of the production process.

Before that, the paper had to follow the process. If a manager wanted to check the progress he (or she) had to find the paper first. After each day all the data from the paper had to be recorded in digital form. Even worse, if there was an unfortunate case when the paper got lost or damaged, all quality assurance had to be done again. A day’s work was lost.

V-Tablet devices serve as information display and data entry point.

With the system we deployed, our V-Tablet devices connect our V-Platform server software and a custom application that takes care of production process. Wireless connection is local and disconnected from Internet to prevent potential risks. Unlike computers, our V-Tablet devices are used only to display and enter information, since all data is centralized, processed and stored on the server to prevent potential data loss from broken, lost or stolen devices.

It is not only the security aspect that is important. An always-connected setup enables real time data flow. As soon as data is entered through a device it’s available to the whole IT system of the company. Management has real time overview of the production process and can respond immediately if a problem or unusual condition occurs.

While working with paper, workers and quality assurance officers had to sign paper documents to assure traceability. When it was necessary to check production process this involved extensive search of documents in the abundant archives of work order sheets. Searching and examining files and documents in the digital archive is much simpler and quicker. Signing is replaced with log-in system available on any device. Different roles are assigned to individuals according to their obligations and responsibilities.

Good visibility and robustness of V-Tablet devices enables use in harsh environments.

There are several reasons why we wouldn’t use a computer or a tablet for such a task. Computer screen and keyboard are impractically big. Both computers and tablets have very limited battery life and need either constant power supply or constant recharging. E-paper uses power only when display is changing image, which means that devices can be simply attached using Velcro strips and removed every two weeks for overnight charging.

An additional bonus is that unlike conventional backlit flat panel displays, e-paper displays reflect light like ordinary paper. Because of this they are comfortable to read even in a very bright environment and have a very wide viewing angle (nearly 180 degrees). Finally, our V-Tablet devices are dust and water resistant which is not the case with computers and other consumer tablet devices.

The end result of simply replacing paper based process with V-Tablets and V-Platform server the whole process got optimized:

- real time monitoring of the production line process and related quality assurance points,

- automated entry of the data in the IT infrastructure,

- replacement of big quantities of paper and easier storage and retrieval of documents (with search capability),

enhanced traceability.

V-Tablet devices replace all paper that was required for the production process.

How can e-paper coupled with V-Platform help me?

You can open a lot of opportunities for enhancing the production process, its monitoring and management by deploying our e-paper solutions. You’ll gain organizational and financial benefits that result in competitive advantage.

As you can see above we successfully deployed our devices on a production line. We’re sure that this kind of optimization would work in the majority of production lines and we would like to hear from you. Our V-Platform can solve some of the issues that you’re running into daily on your production lines.

Browse through our blog to see what else one could build with our V-Platform and V-Tablet devices and sign up for our mailing list to keep up-to-date with new applications for our V-Platform.

Tags